BASIC COOLING

METHODS Forced Ventilation Air Cooling

|

BASIC COOLING METHODS

By

Kooltronics

Forced Ventilation Air Cooling

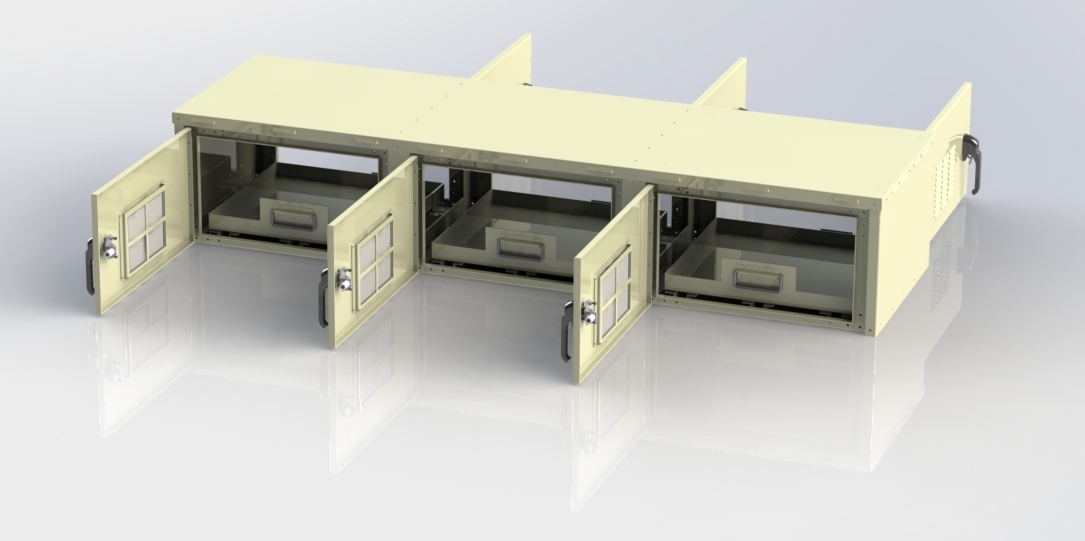

In clean,

non-hazardous environments with

acceptable ambient temperatures, a

simple forced-air cooling system

utilizing ambient air is usually

adequate. Combined with a low-cost

air filter, such devices generally

meet the heat removal needs of

typical electronic and electrical

equipment (Fig. 1).

FIGURE 1

Fans,

Packaged Fans, and Centrifugal

Blowers can be used to pressurize or

exhaust cabinet air. The ambient air

should be filtered before it enters

the cabinet.

Fans,

Packaged Fans, and Centrifugal

Blowers can be used to pressurize or

exhaust cabinet air. The ambient air

should be filtered before it enters

the cabinet.

Packaged Blowers mount to the

internal cabinet mounting rails.

They are used to pressurize the

cabinet and provide filtered ambient

air.

Packaged Blowers mount to the

internal cabinet mounting rails.

They are used to pressurize the

cabinet and provide filtered ambient

air.

IF AMBIENT COOLING AIR CAN

BE USED AND THE SYSTEM HAS

LOW STATIC PRESSURE

USE A FAN

|

IF AMBIENT COOLING AIR CAN

BE USED AND THE SYSTEM HAS

HIGHER STATIC PRESSURE

USE A BLOWER

|

Closed-Loop Cooling

In

harsh environments involving high

temperatures, heavy particulates,

oil, or chemicals capable of

damaging components, ambient air

must be kept out of the enclosure.

Sealed enclosures are generally

used, with closed-loop cooling

consisting of two separate

circulation systems in a single

unit. One system, sealed against the

ambient air, cools and recirculates

the clean cool air throughout the

enclosure. The second system uses

ambient air or water to remove and

discharge the heat.

IF INTERNAL CABINET

TEMPERATURE CAN BE GREATER

THAN THE AMBIENT AIR

USE A HEAT EXCHANGER

|

IF INTERNAL CABINET

TEMPERATURE MUST BE EQUAL TO

OR LOWER THAN THE AMBIENT

AIR

USE AN AIR CONDITIONER

|

A

comprehensive discussion of

Closed-Loop Cooling appears later in

this Design Guide. |

|

FILTRATION

Filtration of contaminated air can be

accomplished in some installations to permit

forced convection cooling of electronic

equipment. Generally, contamination can be

broken down into two major categories:

airborne particulate matter and corrosives.

In most cases, particulate matter can be

filtered out and the air made safe for the

cooling of heat-producing equipment.

However, removal of corrosives by filtration

generally requires processes that are too

costly and/or too airflow restrictive.

Therefore, isolation of the enclosure

contents is usually necessary.

Careful consideration must be given to the

type and severity of the conditions to be

encountered. Filters must be able to protect

the enclosure at the worst-case level of

contamination anticipated. Once the system

is installed, adequate preventive

maintenance is crucial. Filters must be

cleaned or replaced regularly, or means must

be provided for continuous monitoring of the

filter condition.

In order to prevent choking of airflow, it

is important for the filter inlet opening to

be at least as large as the total area of

all air outlets. Inlet and outlet areas

should be determined after allowance for

impedance of grille materials or other

barriers.

Air inlets and outlets should be as far

apart as possible, so the air is forced to

circulate through all heat-producing

components. All air inlets should be

filtered, whether the air enters through a

fan or blower, or directly into the cabinet

for exhausting, when pressurization is not

feasible.

STANDARD FILTERS

Filters used with typical electronic

equipment cooling devices are usually the

viscous-impingement type and are

approximately 65% efficient. They utilize

fibers that have been coated with a

nondrying, tacky substance which traps

particulates as air is drawn through.

Usually constructed of aluminum foil or

flock- coated pleated wire screen, the

filters can be cleaned, recoated and re-used

indefinitely. Often, filters of this type

are used as prefilters in multiple filter

systems to extend the service life of high

efficiency or absolute filters.

HIGH EFFICIENCY FILTERS

High efficiency or absolute filters are

available in efficiencies ranging up to

99.97% on 0.3 micron size particles. The

filter media is a pleated paper which

operates as a strainer, since its openings

are physically smaller than the particulates

it is designed to intercept. This type of

filter offers relatively high resistance to

airflow and is employed only where more

common filter types are incapable of

providing acceptable levels of protection.

In applications where such filters are

required, provision must be made for

adequate airflow to overcome the higher

resistance in addition to the cooling

airflow needed.

FLOW MONITORS

Where higher levels of contamination exist

or can develop rapidly, filtered cooling air

packages should be equipped with some form

of flow monitor. In the event of a reduction

in air delivery below a minimum acceptable

level due to a clogged filter, a

flow-sensing or temperature-sensing device

triggers warning alarms or shuts down

affected equipment.

Pressure differential switches, which

respond to pressure drops across an air

filter, are often employed, as are simple

vane-type airflow velocity sensors or

thermostatic over-temperature detectors

located at equipment hot spots. At times,

flow- and temperature-sensing devices are

employed in combination. In this way,

relatively low airflows are accepted when

the ambient temperature is low.

At higher ambient temperatures, reduced

airflow, resulting in excessive component

temperature, activates the warning device or

shuts off power. This arrangement permits

maximum filter utilization and safety to the

equipment.

The need for flow monitoring should be

evaluated carefully because of the added

cost of the various devices required.

VARIABLE SPEED BLOWERS

The optimum open-cycle system for use in

contaminated environments combines

appropriate air filters and cooling-effect

detectors with a variable speed blower that

adjusts its operating speed to provide the

desired cabinet air temperature, as sensed

at some point within the enclosure. Since

blower air delivery is directly proportional

to motor shaft speed, airflow rate can be

adjusted to a minimum compatible with a

clean air filter and low ambient

temperature. Should ambient temperature

increase or the filter clog with

contaminants, the sensor and controls would

demand an increase in motor speed until the

new conditions were satisfied.

The variable speed blower is self-adaptive

to changes in ambient temperature, air

density, line voltage, power dissipation in

the enclosure, and to the degree of

filter-loading. Since the blower operates at

the minimum speed and air delivery

compatible with cooling, both power

consumption and the rate of contaminant

accumulation on filter surfaces is greatly

reduced, compared to a constant speed blower

designed to satisfy worst-case conditions.

This increases filter life and reduces

filter maintenance to a minimum. Conversely,

as the filter loads, blower air delivery

could increase to levels beyond those that

would be obtained under constant speed

conditions. Again, cost must be considered.

|

CORROSIVE ATMOSPHERES

Corrosive environments, such as those found

in chemical plants and in industries where

processes result in harsh chemical

by-products, usually preclude the use of

filtered ambient air for forced convection

cooling. Corrosives generally cannot be

filtered out by normal filtration methods,

and scrubbing techniques that must be used

to rid air of corrosives are complex,

costly, and often not satisfactory.

For such applications, the cooling method

requires isolation of the sensitive

components subject to damage from the

offending substances. The solution is

usually closed-loop cooling - Heat

Exchangers or Air Conditioners which

consists of two separate circulation systems

in a single unit. One recirculates clean

cooling air through the electronics within

the sealed enclosure, while the other

discharges the heat removed from the cabinet

to the ambient air or into water for

removal.

If the corrosive atmosphere is normally

within an acceptable temperature range,

air-to-air Heat Exchangers can be used to

provide cooling for equipment enclosure.

When both high ambient temperatures and

corrosives are present, either Air

Conditioners or water-to-air Heat Exchangers

must be employed to cool the hot components.

Regardless of the cooling apparatus chosen,

it must be constructed of appropriate

corrosion-resistant materials, or be treated

with corrosive-resistant coatings, to ensure

long, trouble-free operation under the

conditions to be encountered.

Care should be taken to review the

particular conditions involved. In most

cases, a system can be designed to meet

specific requirements at moderate cost.

|

|

CLOSED-LOOP COOLING

Many applications using

sophisticated electronic/electrical

components require a closed-loop

cooling system to dissipate heat

buildup without introducing outside

contaminated air. Closed-loop

cooling is required when equipment

is operated in hostile environments

containing dirt, oil, humidity or

corrosives, which adversely affect

the performance or ultimate survival

of the components. The presence of

airborne particulate matter

compounds the difficulty of

controlling the temperature of the

equipment in the enclosure.

HEAT EXCHANGERS

For installations that can operate

at above-ambient temperatures, Heat

Exchangers provide moderate-cost

closed-loop cooling. Available in

both air-to-air and water-to-air

versions, there are models covering

a wide range of cabinet sizes and

performance capacities. Depending

upon the model selected and the heat

load, near-ambient to

moderately-above-ambient

temperatures can be achieved.

For applications that can utilize

Heat Exchangers, the advantages

compared with Air Conditioners

include:

-

Lower initial cost

-

Lower power consumption

-

Simpler construction

-

Fewer operating components

-

Lighter weight

AIR-TO-AIR HEAT EXCHANGERS

Advanced air-to-air Heat Exchanger

designs for cooling enclosures

include two types of heat transfer

methods. One design consists of a

finned-tube coil which contains

liquid refrigerant. The warm air

exhausted from the equipment cabinet

to the Heat Exchanger is directed

past the coil, causing the

refrigerant to boil and absorb heat.

The resultant refrigerant vapor

rises to the upper portion of the

tubes, where the heat is removed by

the cooler ambient air and the

refrigerant condenses back to

liquid, completing the cooling cycle

in a continuous process.

The most recent developments in

enclosure Heat Exchanger design

employ high-efficiency heat transfer

elements fabricated of embossed

convoluted metal foil or thin-film

polymer material, constructed into

two totally separate air paths. The

air leaving the hot enclosure is

directed through one side of the

exchanger, where the heat passes

through the element walls into the

ambient-side airstream and is

dissipated.

Figure 3 illustrates heat transfer

in air-to-air Heat Exchanger

applications.

WATER-TO-AIR HEAT EXCHANGERS

If ambient air

cannot be utilized directly as a

cooling medium, another

cost-effective method of cooling is

a water-to-air system (Fig.4). Water

is used to remove heat from air

circulated within the electronic or

electrical enclosure.

Cooling water is

circulated through a finned-tube

coil, which is installed in a

compartment isolated from the

enclosure to protect the contents

from possible leakage of water. As

the heat-laden air circulates

through the coil, the heat is

absorbed by the water and carried

away, in a continuous process.

Water-to-air

systems are easy to install and

usually require minimum maintenance.

The water used must be reasonably

clean and cold enough to ensure

proper operation of the cooling

system under the most severe

anticipated conditions.

In cases where

sufficiently cold water is

available, below ambient-temperature

cooling can be achieved. |

|

|

AIR

CONDITIONERS

Air Conditioners

are required where the equipment

operating temperature must be kept

at or lower than the ambient room

temperature, and/or the cabinet must

be sealed from oil, dust, fumes and

other contaminants.

Specially packaged

vapor compression Air Conditioners

(Fig. 5) protect the components and

furnish the required cooling. Such

Air Condition-ers employ hermetic

refrigeration systems with

additional controls. They provide

enclosure and air-path geometries

for direct installation to the

equipment cabinet and accomplish the

following:

- Isolate the

interior of the equipment

enclosure from ambient

conditions

- Cool the air

within the enclosure to the

optimum temperature for the

sensitive components

- Circulate the

air within the enclosure to

equalize temperature and

increase heat transfer from hot

components

- Automatically

vary cooling rate to maintain

close control of equipment

temperature

- Reduce

humidity harmful to sensitive

components

Air Conditioners that

are used to cool enclosed equipment

differ radically from room Air

Conditioners. In the area of

temperature control, for example,

most electronic systems are

adversely affected by large line

transients typical of Air

Conditioner compressor cycling.

Electronics also exhibit sensitivity

to electromagnetic interference

caused by thermostat contacts. The

control system of an Air

Conditioning package must be

designed accordingly.

In addition, the

field experience of many compressor

manufacturers has indicated that the

frequent start/stop cycling, typical

of standard Air Conditioner

operation, shortens compressor life.

These factors have

led to the develop-meant of

techniques for close control of

internal temperature over a wide

range of ambient conditions, without

turning the refrigeration compressor

on and off and without employing

electrically-controlled solenoid

valves.

All temperature

control for KOOLTRONIC Air

Conditioners is accomplished by

means of proportioning valves

activated by pressure signals within

the Air Conditioner hermetic system.

Generally, load temperature can be

controlled to �5�F over a range of

power dissipation, without the use

of thermostats. Frequent start/stop

cycling of the compressor is

eliminated, thus assuring longer

compressor life.

Recent

developments in temperature

requirements for enclosed components

has led to the addition of

adjustable Low Temperature Control

thermostats in all KOOLTRONIC Air

Conditioners to prevent

over-cooling. EMI/RFI suppressors

are included to control the line

transients associated with

compressor cycling and thermostat

operation.

Hermetic Air

Conditioners are available in

air-cooled and water-cooled models.

AIR-COOLED AIR CONDITIONERS

Heat removed from

the enclosure containing hot

components is discharged by

circulating the ambient air through

the condenser coil and returning the

heated air to the ambient. There are

vertical and horizontal types for

exterior mounting to side panels,

doors, or the top of the enclosures,

and for various internal positions.

WATER-COOLED AIR CONDITIONERS

Intended primarily

for extreme operating conditions of

high-ambient temperatures or severe

contaminants, these units utilize

water as the medium for heat

dissipation. The heat is absorbed by

cool water circulating through a

coaxial condenser coil, following

which the heat-laden water is

discharged or recalculated after

cooling |

|

|

VAPOR

COMPRESSION CYCLE

Heat is removed by

enclosure Air Conditioners and

discharged by means of the vapor

compressor refrigeration cycle. This

takes place in a hermetically sealed

system, utilizing either an

air-cooled or water- cooled

condenser heat exchanger. A

schematic ofa typical Air

Conditioner is presented in Figure

6.

The compressor

forces refrigerant, in vapor form,

into the condenser heat exchanger,

where it is cooled either by ambient

air, driven between the fins by a

specially engineered blower, or by

cool circulating water. As it cools,

the refrigerant condenses into

liquid, which is passed through a

filter to remove impurities and

excess moisture. The liquid

refrigerant flow is metered by a

thermostatic expansion valve or

capillary tube, to control its

admission to the evaporator.

The thermostatic

expansion valve is a feedback control

device which regulates refrigerant

flow on the basis of conditions

sensed at the evaporator outlet. The

capillary tube is a long,

small-diameter tube which employs

pressure differential and complex

two-phase internal flow dynamics to

meter refrigerant to the evaporator.

The refrigerant

enters the evaporator as a liquid

beginning to vaporize. As the

blower-driven heated air from the

enclosure passes through the

evaporator heat exchanger,

the refrigerant absorbs the heat and

the conversion to vapor is

completed. Any moisture present in

the air is removed by condensation.

This cool, dehumidified air is then

returned to the cabinet.

After the heat

absorption phase, the refrigerant

passes into an accumulator, where

any remaining vaporized liquid is

separated. The gas then returns to

the compressor, to repeat the cycle

in a continuous process.

The total heat

rejected at the condenser is all of

the heat entering the system from

the enclosure at the evaporator heat

exchanger, heat of compression and

heat rejected by the compressor

motor, since the compressor is

cooled by the refrigerant gas

returning from the evaporator.

Typical air

temperatures during the cooling

process are: cooled air to

enclosure, 75�F; heated air returning

from enclosure, 100�F; ambient air

cooling condenser,105�F; air

rejected from condenser, 140�F.

TEMPERATURE CONTROL

Typical

refrigeration and Air Conditioning

systems control temperature by

on/off compressor cyclingas air

temperatures fluctuate between

minimum and maximum thermostat

settings. Compressor start-up often

introduces substantial transients

into the circuit powering the

equipment to be cooled. Thermostat

or relay operation results in

electromagnetic inter- ference. Both

of these factors can adversely

affect

the function of electronic

equipment. On/off compressor control

necessitates choosing between large

temperature excursions or frequent

compressor cycling.

Furthermore,

frequent start/stop operation exposes

internal compressor components to

electrical and mechanical strains not

encountered during continuous

operation. The use of

electrical controls to handle high

compressor start-currents results in

eventual erosion of the control

contacts themselves.

In order to

eliminate the possibility of these

problems, KOOLTRONIC Air

Conditioners feature a

continuously operating compressor and

non-electric proportional control

system, which result in more stable

equipment temperatures and prolonged

life for the compressor and the

control system. Both blowers and the

compressor start simultaneously with

the application of power to the

unit, and continue to operate until

power

is removed at the time of equipment

shutdown.

The control bypass

valve, shown in Figure 6, permits

refrigerant, in gas phase, to be

injected at the inlet to the

evaporator heat exchanger. This

high-temperature, high-energy gas

presents an artificial heat load and

permits the effective cooling rate to

be varied as necessary to maintain

essentially constant temperature of

the air returned to the enclosure.

(It is normally factory set to

deliver air at approximately 70�F.)

This control also prevents

evaporator freeze-upsdur-ing periods

of low heat load or low ambient

temperature.

Although the

above control system works

effectively at most times, there are

instances of over-cooling due to low

heat load or low ambient

temperature. In order to prevent

that condition, Low Temperature

Control thermostats and EMI/RFI

suppressors have been added to all

KOOLTRONIC Air Conditioners.

When activated,

the Low Temperature Control shuts off

the compressor and condenser

(ambient side) blowers. The

evaporator (enclosure side) blowers

continue to circulate the air

through the enclosure and Air

Conditioner. When the air

temperature again reaches the level

at which cooling is needed, the

compressor and condenser

blowers r�sum� operation.

AMBIENT TEMPERATURE RANGE

Most KOOLTRONIC

Air Conditioners are designed to

operate at ambient temperatures

ranging from 50�F to131�F. Optional

Low Ambient Kits allow operation in

ambient temperatures as low as 0�F.

Maximum operating

ambient temperature decreases

linearly with altitude at the rate

of 3�F per1,000 feet between 2,500

and 7,500 feet, where maximum

operating ambient temperature is

110�F. The ability to operate at

high ambient temperatures permits

KOOLTRONIC Air Conditioners to be

installed in close proximity to

furnaces and other heat-producing

equipment.

For applications

in ambienttem-peratures higher than

the rated

maximum, consultation with the

KOOLTRONIC Engineering Depart-ment

often provides the solution.

CONDENSATION

High ambient

relative humidity does not affect the

rated capacities of KOOLTRONIC Air

Conditioners. They're designed for

installation on reasonably tight

enclosures of relatively limited

internal volume.

Normally, only

sensible heat loads are imposed on

the Air Conditioner. Even at an

ambient temperature of 95�F and a

relative humidity of 100%, the air

within a typical electronic

equipment

enclosure 21/2 feet square and 6

feet high will contain only small

amount of water in vapor form. As

the temperature of the air

being circulated within the enclosure

is reduced from 95�F to 70�F,

theater will be condensed quickly

in the evaporator heat exchanger and

be disposed of through the drain in

the condensate tray at the bottom of

their Conditioner.

Unless the

enclosure is totally sealed, some

slow invasion of ambient air will

take place through cracks and seams

in the cabinetry and the front

panels. However, even at

ambient relative humidifies of 100%,

the infiltration rate is normally so

small that the effect on cooling

capacity of latent heat of water

vapor condensation in the

infiltrating air

is negligible.

Cooling

performance of the Air Conditioner is

reduced if its capacity is used for

the condensation of excessive

moisture. This occurs if the

enclosure is poorly sealed oris open

for long periods, under high

humidity conditions. A

continuous flow of condensate denotes

that these adverse conditions are

present and should be remedied

immediately. |

|

|

SIZING CLOSED-LOOP COOLING EQUIPMENT

In forced

convection cooling of enclosures,

cooler ambient air is drawn or

forced through the components in an

enclosure and discharged. When

electronic/electrical enclosures are

sealed to keep out moisture, dust,

dirt and other contaminants, the

heat generated by the components is

trapped and closed-loop cooling (air

conditioner or heat exchanger) is

needed to maintain the optimum

environment for the components.

The heat generated

by the components is the INTERNAL

HEAT LOAD. Because of the internal

heat being generated, there is

typically a temperature differential

between the inside and the ambient

air outside the enclosure. Heat is

conducted through the exposed area

of the enclosure from the warmer to

the cooler space, and is known as

the HEAT LOAD TRANSFER. Since Air

Conditioners cool to below ambient,

the Heat Load Transfer is a heat

gain into the enclosure, whereas

it is a heat loss out of the

enclosure when Air-to-Air Heat

Exchangers are used because they do

not cool to below the ambient.

When sizing an Air

Conditioner or Heat Exchanger using

the methods on the following pages,

if the Internal Heat Load (in Watts

or BTU/Hr.) is known, it is the

value used in Step One. When

it is not known, there are several

methods of estimating, including (1)

Component Rated Heat Production;

(2) Air Flow Heat Rise; (3) Sealed

Enclosure Temperature; (4)

Incoming-Outgoing Power; and (5)

Component Efficiency. Of these, the

most accurate and least

time-consuming is Method (3), which

is the method we recommend for

uninsulated enclosures.

The following

steps should be followed:

(A) The Enclosure

must be operating at its highest

work load.

(B) All openings are sealed and

air-moving equipment turned off.

(C) Measure the inside air

temperature near the top of the

Enclosure.

(D) Measure the ambient air

temperature and determine the

differential.

(E) Calculate the exposed

surface area of the Enclosure

(sides and top) in square feet.

(F) Refer to the Temperature

Differential Heat Gain/Loss

Chart, at the temperature

differential determined in (D)

and multiply the Watts/Square

Foot by the exposed area (E).

This is the approximate

Internal Heat Load in Watts.

For BTU/Hr, multiply by 3.413.

The Heat Load

Transfer calculations required are

provided in Steps Two and

Three under Heat Exchanger

Sizing and Selection or

Air Conditioner Sizing and

Selection.

TEMPERATURE DIFFERENTIAL HEAT

GAIN/LOSS CHART

FOR

UNINSULATED ENCLOSURES

|

|

|

AIR CONDITIONER SIZING AND SELECTION

Air Conditioners for cooling

electronic/electrical enclosures

should be selected to provide

adequate cooling for the anticipated

worst-case conditions. For best

results, Panel-Mounted Air

Conditioners should have the

cool air inlet at or below the

lowest significant heat-producing

component and the return air port

should be above the highest such

component.

The capacity (BTU/Hr) should be

approximately equal to the Internal

Heat Load plus the Heat Load

Transfer (see Sizing Closed-Loop

Cooling Equipment), but should not

be over-sized, as this will result

in excessive cooling which may

affect component performance or

cause “sweating” of the Enclosure

during high humidity conditions.

Normally, no additional provision is

needed for the humidity in the

Enclosure at start-up because it

will be dissipated very quickly from

a properly-sealed Enclosure.

A

determination should be made of the

appropriate mounting position—side

panel, door, internal or top.

Although most KOOLTRONIC Air

Conditioners are equipped with

Condensate Evaporators (or are

available as an option) and all have

condensate drains, it is preferable

to not place an Air Conditioner

directly above electronic/

electrical components if the

application is likely to be subject

to high humidity, which will

infiltrate an imperfectly sealed

cabinet.

The

maximum allowable internal cabinet

temperature (Ti) should not exceed

the heat tolerance specification of

the most sensitive component in your

system.

NOTE: This selection process

applies only to indoor gasketed

enclosures which are uninsulated.

Before proceeding, read Sizing

Closed-Loop Cooling Equipment.

For applications involving outdoor

locations, solar load, non-metallic

or insulated enclosures, consult

KOOLTRONIC for assistance.

The model numbers of KOOLTRONIC Air

Conditioners reflect the

refrigerant, as of the publication

date. A 4 between the A and C

signifies R134a; a 3 signifies R22.

The Technical Data shown is as

determined by testing for UL

certification. As more R134a-type

compressors become available, R22

units will be redesigned for R134a

which may affect performance.

TO DETERMINE REQUIRED AIR

CONDITIONER CAPACITY

|

|

|

|

AT EXCHANGER SIZING AND SELECTION

The proper selection of a Heat

Exchanger is determined by how many

WATTS can be dissipated at a given

temperature differential. Since a

Heat Exchanger uses ambient air or

available water for cooling, the

enclosure cannot be cooled below a

temperature slightly above that of

the air or water entering the Heat

Exchanger. Therefore, the greater the

temperature differential, the higher

the capacity of the Heat Exchanger.

Consequently, the smaller the

temperature differential required in

an application, the higher the

capacity of the Heat Exchanger

needed to achieve it.

The amount of heat to be dissipated

is the Internal Heat Load less

the Heat Load Transfer (heat

conducted through the uninsulated

walls of the enclosure).

The performance of Heat Exchangers

is expressed in WATTS/�F. In the

preferred “Air In” method, the

Watts/�F depicts the amount of heat

the Heat Exchanger is capable of

dissipating per degree Fahrenheit of

temperature differential between the

entering air or water temperature

and the maximum allowable internal

enclosure temperature. The

calculation process requires (a) the

amount of heat to be dissipated, (b)

entering air or water temperature,

(c) maximum allowable internal

enclosure temperature and (d) the

dimensions of the enclosure.

The maximum allowable internal

cabinet temperature (Ti) should not

exceed the heat tolerance

specification of the most sensitive

component in your system.

NOTE: This selection process

applies only to indoor gasketed

enclosures which are uninsulated.

Before proceeding, read

Sizing Closed-Loop Cooling

Equipment. For applications

involving outdoor locations, solar

load, non-metallic or insulated

enclosures, consult KOOLTRONIC for

assistance.

TO DETERMINE REQUIRED HEAT EXCHANGER

PERFORMANCE IN WATTS/�F—Air In

Method

This is the rating (Watts/�F Air In)

based on the temperature of the air

into the heat exchanger, after

exiting the hottest area of the

enclosure. Refer to the Heat

Exchanger Index and Selection Guide

for the unit that most nearly

matches the required performance and

dimensions.

Another rating, (Watts/�F Air Out)

is based on the lower temperature of

the cool air as it exits the heat

exchanger into the enclosure. This

rating may be used if the coolest

air can be directed for spot cooling

of components in the portion of the

enclosure where the air enters from

the heat exchanger.

|

|

|

|

OkSolar.com Affiliate

|

Adobe

PDF Files Many OkSolar documents & catalog pages

require

the latest version of Adobe Acrobat Reader that may

be downloaded free at: You can get this application

for Free at

https://www.oksolar.com/pdf require

the latest version of Adobe Acrobat Reader that may

be downloaded free at: You can get this application

for Free at

https://www.oksolar.com/pdf

|